FABRIC-LEGO

Medical braces and assistive wearables serve critical functions in

supporting mobility and aiding individuals with temporary disabilities. However, these devices often lack aesthetic appeal and

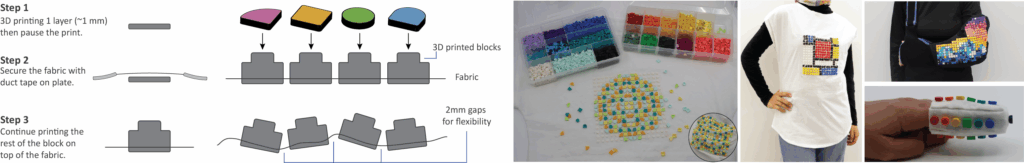

fail to provide personal expression, leading to psychological challenges and social stigma. We propose a novel fabrication method,

Fabric-Lego, which combines 3D-printing with traditional garmentmaking (pattern-making, sewing, ironing, and overlocking) to address these shortcomings. By integrating customizable Lego®-like

blocks into wearable fabrics in accessible DIY ways, users can personalize their wearables while maintaining comfort and functionality. We present the fabrication process, including insights on

materiality, pre-processing, 3D-printing, and post-processing steps.

To demonstrate the design space and potential applications of our

method, we implemented 3 prototypes: 1) a customizable arm sling

cover, 2) a customizable fnger splint cover, and 3) a T-shirt with

integrated blocks. This approach ofers a promising path for enhancing the user experience and empowering individuals to embrace

their unique identities.

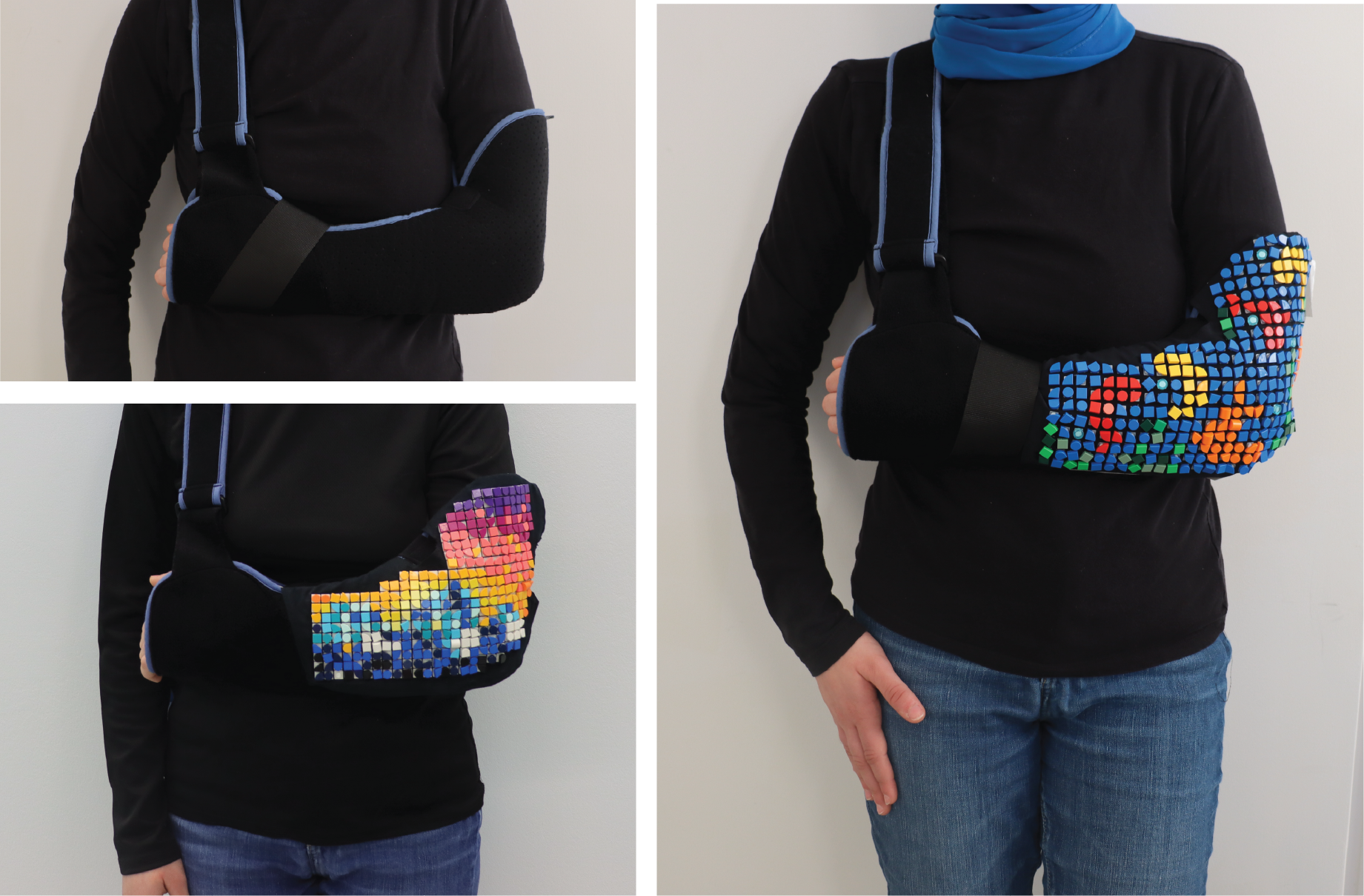

The first application consists of an attachable cover for an of-the-shelf assistive arm sling that is used as a shoulder/elbow immobilizer. To design its Fabric-Lego cover, we created

a paper grid pattern, using the same measurements of the sling,

marking where each block is located, and cut it to size assuring

it would fit correctly. Using this grid, we transitioned the design

layout of the bricks onto a 3D model to print. Then, we used plain

black 100% cotton fabric and cut it to size, keeping a 2cm seam

allowance around all sides. Once we integrated the blocks using

the method above, we stitched snap-buttons onto the top side of

the sling and arm sling as well as Velcro on the bottom to allow a

snug ft. This cover allows for personalization and self-expression

of an otherwise plain coloured or hostile looking medical brace.

The third application consists of a t-shirt with the blocks integrated

in a 16x16 grid in the middle of the front bodice. We

cut a 2-piece t-shirt pattern from plain white 100% cotton fabric and

used the front side to 3D-print the Fabric-Lego. After the frst/base

layer of all the blocks were printed, we secured the shirt’s front to

the build plate of the 3D printer, making sure to keep it fat and

create tension ensuring the following layers of blocks will adhere.

After 3D-printing was done, the front and back sides were machinesewn with straight stitches and secured with an overlock machine’s

coverstitch. The curved neck line and bottom hems were pinned

and ironed inwards before serging for a clean fnish. With this approach, users can download and customize designs to upcycle their

everyday garments rather than constantly replacing them. This

opens the door for new personalized aesthetics (breaking norms

of imposed trends) supported by personal fabrication that reduces

fast fashion and ofers opportunities for sustainability alongside

personal expression.

Video:

Publication

Acknowledgment

This project was funded by the National Sciences and Engineering

Research Council of Canada (NSERC) through a Discovery Grant

(2021-04135), its Discovery Supplementary Fund (2021-00310), as

well as through a Queen’s Research Initiation Grant (RIG). We

acknowledge the support of Ontario Research Fund and Canadian

Foundation for Innovation for this research.